Welcome~Guizhou Vilong Equipment Co,.Ltd

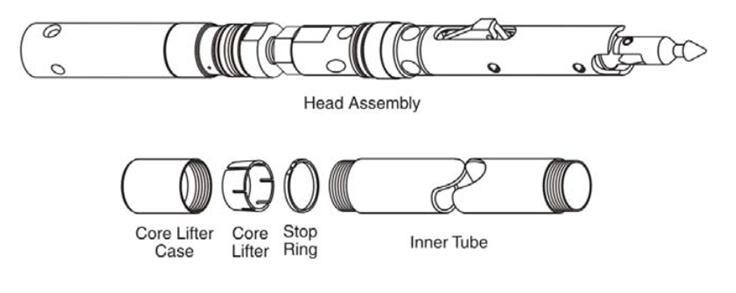

An inner tube Consists of the head assembly, inner tube, stop ring, core lifter, and core lifter case.

1. Apply a light coating of lithium grease to the inside of the

core lifter case.

2. Slide the core lifter into the threaded end of the core case, tapered

end first. The tapered surfaces of the core lifter and core lifter case act

against one another to tighten the grip on the core when the core barrel is pulled back.

3. Snap the stop ring into the core lifter case. The stop ring

provides a hardened surface for the core lifter to bear against during coring.

4. Thread the core lifter case onto one end of the inner tube.

5. Thread the head assembly on to the other end of the inner tube.

6. An optional inner tube liner or “split tube” with a pump-out system is available, which is commonly selected when drilling coal, clay bearing or highly fractured formations, a core ejection piston protects the core from pressurized drilling fluid when the split tube, containing the core sample, is pumped out of the inner tube.

NOTE: Tighten all joints with an inner tube wrench.

Contact: Mr. Peter Chan

Phone: +86 851 8577 3056 / 8569

Email:sales@rotarypercussivedrill.com

Add:No.17, 21 floor, unit 1, 1 building, M district, xiaochehe street flower orchard project, Nanming district, Guiyang City, Guizhou Province, China.