Welcome~Guizhou Vilong Equipment Co,.Ltd

In DTH drilling, the percussive DTH hammer is located behind the drill bit, inside the hammer, a piston powered by compressed air gives the DTH drill bit its striking power, while the DTH hammer casing gives guidance to the DTH drill bit; the drill string rotates while the drilling hammer continuously strikes down into the rock. The DTH drill rods transmit the necessary feed force and rotation to the DTH hammer and bit, as well as compressed air for the DTH hammer, more drill rods are added to the top of the drill string as the hole gets deeper. The fast hammer impact breaks hard rock into small particles, which are blown up by the air exhaust from the DTH hammer.

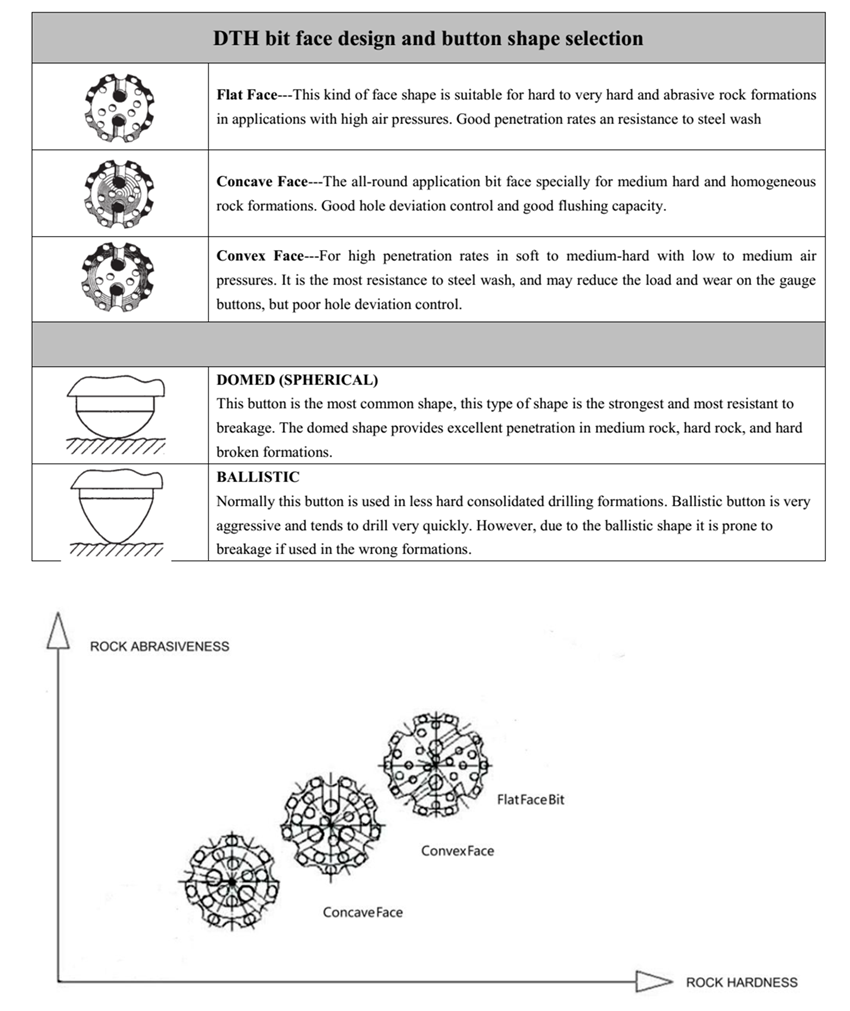

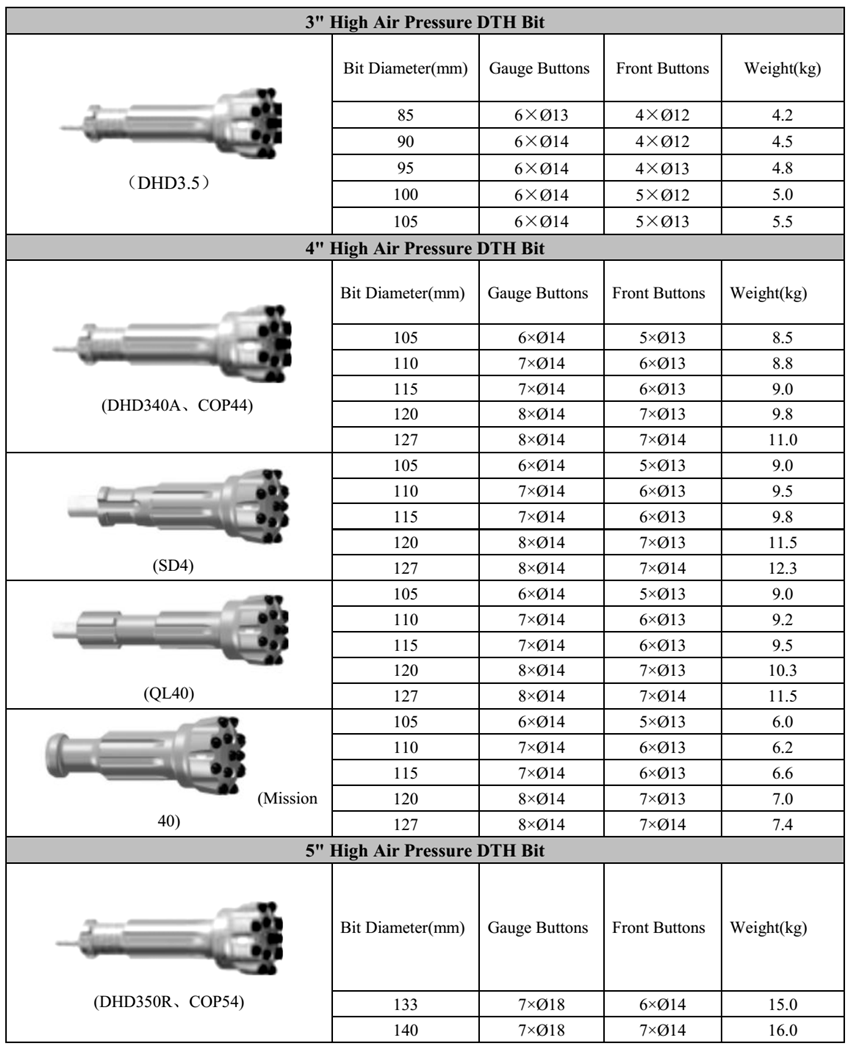

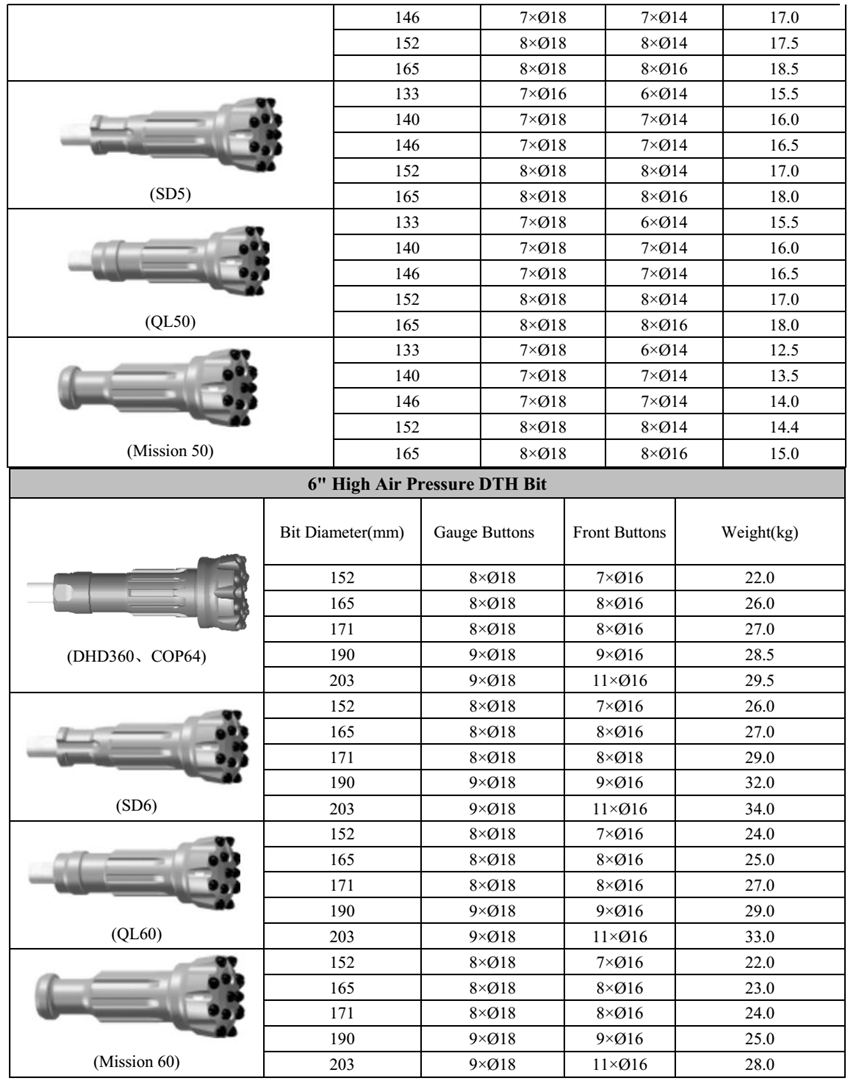

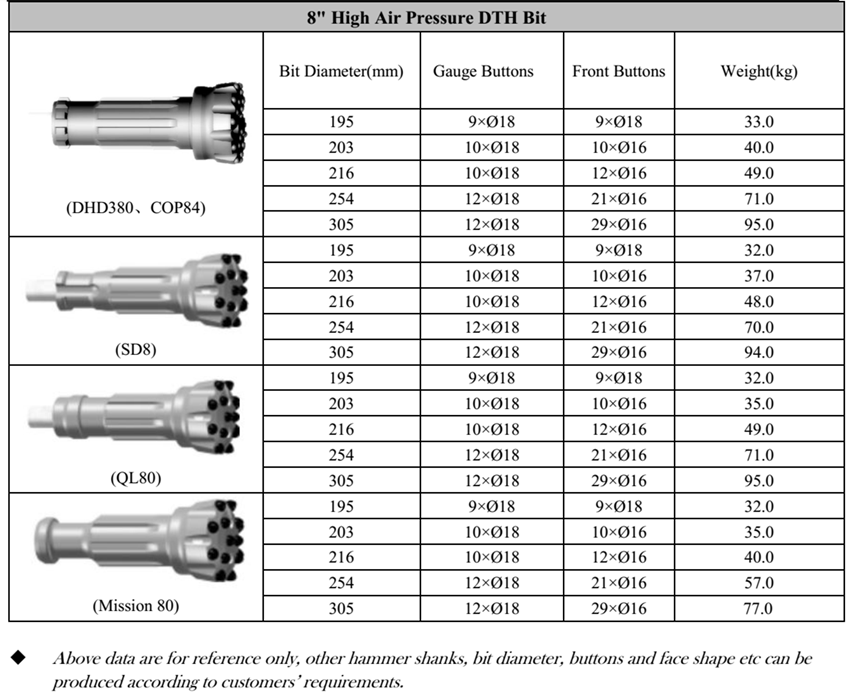

We supply a comprehensive range of DTH Drill Bits in DHD, QL, SD and Mission etc shanks to suit all types of applications and drilling processes. Standard DTH bits are flat face and spherical buttons, with all other designs available.

Common DTH hammer shanks:

Atlas Copco: COP32, COP34, COP44, COP54, COP64, COP84 …

Ingersoll Rand: IR3.5, DHD340, DHD350, DHD360, DHD380, QL40, QL50, QL60, QL80...

Sandvick Mission: M40, M50, M60, M80, SD4, SD5, SD6, SD8, SD10, SD12...

Halco: MACH303, DART350, MACH44, DOMINATOR400, MACH50, MACH60...

Contact: Mr. Peter Chan

Phone: +86 851 8577 3056 / 8569

Email:sales@rotarypercussivedrill.com

Add:No.17, 21 floor, unit 1, 1 building, M district, xiaochehe street flower orchard project, Nanming district, Guiyang City, Guizhou Province, China.