Welcome~Guizhou Vilong Equipment Co,.Ltd

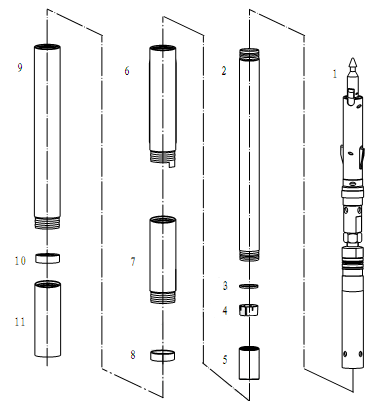

Core barrel part details

|

Item |

Name |

Qty |

|

1 |

Head assembly |

1 |

|

2 |

Inner tube |

1 |

|

3 |

Stop ring |

1 |

|

4 |

Core lifter |

1 |

|

5 |

Core lifter case |

1 |

|

6 |

Locking coupling |

1 |

|

7 |

Adapter sub |

1 |

|

8 |

Landing ring |

1 |

|

9 |

Outer tube |

1 |

|

10 |

Inner tube stabilizer |

1 |

|

11 |

Thread protector case |

1 |

|

Weight |

Item 1 (kg) |

Item 2-11 (kg) |

|

BQ 1.5m length |

6.5 |

24.8 |

|

BQ 3m length |

6.5 |

35.8 |

|

NQ 1.5m length |

12.5 |

37.2 |

|

NQ 3m length |

12.5 |

59.7 |

|

HQ 1.5m length |

19.2 |

49.5 |

|

HQ 3m length |

19.2 |

87.3 |

|

PQ 1.5m length |

30 |

72.5 |

|

PQ 3m length |

30 |

117 |

A core barrel is used to collect core samples, which guarantee the core samples not drop out of the inside of the core barrel when lifted. There are standard AQ, BQ, NQ, HQ, PQ etc sizes of double tube core barrel and NQ3, HQ3, PQ3 etc sizes of triple tube core barrel, main parts overview are as below:

1. HEAD ASSEMBLY

The head assembly provides: latching and pivoting spear point mechanisms to allow insertion and retrieval of the inner tube assembly, a bearing assembly to allow the inner tube to remain stationary and avoid sample damage while drilling, fluid pressure operating indications and fluid control valves. All head assemblies incorporate a shut off valve assembly which provides a fluid pressure signal to the drill operator when the valve members are compressed, indicating a full or blocked inner tube.

2. INNER TUBE

The inner tube captures the core sample as drilling progresses. Multiple inner-tubes can be assembled with couplers or extensions to accept longer core samples.

3. STOP RING

The Stop Ring is hardened steel snap ring designed to seat into a mating groove, and retain the core lifter in the core lifter case.

4. CORE LIFTER

The core lifter is a hardened steel, split collar with a tapered body that mates to a tapered socket in the core lifter case. In a core breaking operation, the drill string is lifted off bottom and the core sample begins to slide out of the inner-tube. Grip features on the inner surface of the core lifter catch the moving core sample and pull the core lifter towards the smaller end of the tapered socket in the core lifter case. The core lifter is constricted against the core sample and retains it after it has broken, allowing retrieval to surface.

5. CORE LIFTER CASE

The core lifter case mates to the inner tube and houses the core lifter in a tapered socket which controls movement of the core lifter. As the drill string is lifted during a core breaking operation, the core lifter case bottoms out on the inside of the drill bit transferring the pullback load from the drill string to the core lifter until the core sample breaks.

6. LOCKING COUPLING

The locking coupling threads to the drill rod string and provides a hardened mating surface which the core barrel inner tube assembly latches ride against while drilling. Additionally, locking couplings provide directional control for the core barrel assembly through wear resistant stabilizing pads which abrade against the drill hole wall.

7. ADAPTER SUB

The adapter sub or called adapter coupling mates between the locking coupling and core barrel outer-tube, providing the pocket into which the head assembly latches deploy.

9. OUTER TUBE

The outer tube houses the inner tube assembly and connects to the diamond bits cutting the hole. The increased wall thickness of the outer-tube provides additional stiffness for directional control and a tighter hole annulus for increased fluid velocity and rapid cuttings evacuation for bit performance. Multiple outer-tubes can be assembled to extend the possible core sample length.

10. INNER TUBE STABILIZER

The inner tube stabilizer or simply called stabilizer is seated in the reaming shell or in mated outer tube extensions the replaceable and reversible inner tube Stabilizer provides centralizing for improved sample recovery and a bearing between the stationary inner tube and the rotating outer tube.

Contact: Mr. Peter Chan

Phone: +86 851 8577 3056 / 8569

Email:sales@rotarypercussivedrill.com

Add:No.17, 21 floor, unit 1, 1 building, M district, xiaochehe street flower orchard project, Nanming district, Guiyang City, Guizhou Province, China.